1.3.1 to 1.3.5

Course subject(s)

1. Track, Train and Movement

1.3.1 Heavy Rail

Why are you able to see through multiple carriages in modern designs, but not older ones? What enables this?

Heavy rail is a term for regular trains and infrastructure. In this MOOC, we will use this term to introduce passenger transport trains as well as heterogeneous transport. The structure and design of passenger trains has changed quite a lot over the years. One very recognisable one is that in the past a train consisted of a clearly recognisable locomotive and several cars (or coaches), which were connected by transit locks (vestibuled). Modern trains feel more open, and more often, you can actually see through the train from end-to-end. This makes it much more spacious and it comes with a feeling of safety, but an important additional advantage is that this limits the damage to the track.

To make this possible, the wheel-sets had to be repositioned. At first, each car/wagon had a bogie on both sides, making them independent in use, but – when connected – the result is two bogies very close to each other. When making a turn or when passing a switch, this created a notable difference in where the end of each car would be. This affected, not only the relative position of both cars, but also the space needed to make this happen. A much larger additional space resulted in the rubber tubes (transit locks) acting as a buffer between different cars. In the new situation, a shared bogie connects two cars, enabling them to be placed much closer together. Individual cars are usually slightly shortened by using this combined solution, but the full train still uses fewer bogies compared to the old situation. As an additional advantage, this saves weight and limits maintenance.

Heterogeneous train traffic

If local and interstate trains are combined on the same infrastructure (sometimes even with freight and/or high speed trains), we call this heterogenous train traffic. Multiple types of trains using the same track saves space and development costs, but also brings additional challenges. Forces on the track are different for each type, creating more wear and tear to the material (more on this in week 5). In addition, combining local trains, interstate trains and even freight trains, complicates timetabling. Apart from the operational challenges and increased track damage, it creates wide diversity on the track.

(All photos copyright TU Delft)

In the Netherlands, we have a dense network in which interstate trains travel between the larger cities and local trains stop at each station using the same tracks. On average, every ten minutes, a train runs by in each direction, leaving very limited space to fit in freight transport and high speed. This is why important international connections have their own infrastructure, which creates independent timetabling, as well as a track, which is specially designed for the specific type of train. Not only is this much faster and minimises damage, but it also is much more reliable.

Apart from external factors, most issues within the railway network originate from switches. With a separate track for each train (type), the need for switches is much lower, thus giving a lower chance of problems.

The most reliable way to run trains is either in separate lines (like metro) or in circles. People might need to switch trains more often, but when the reliability increases, many people won’t mind. Using only one type of train on specific tracks enables a much denser schedule and less damage to the infrastructure. In case something happens on one of the lines, it will not interfere with the scheduled trains on other lines. We will take a closer look at this unbundling of different trains for different purposes/distances in week 2 and 3.

Multiple units

Especially on rail networks used a lot for commuter traffic, traditional trains with locomotive and towed cars are considered not flexible enough. On these tracks, most of the time, Multiple Unit (MU) passenger trains are utilised. MU’s consist of two or more passenger cars, and have a driver cabin at both ends. MU’s don’t have a dedicated locomotive, but have one or multiple bogies which power the train. This can be both from diesel or electric engines.

The big advantage of MU’s is that during peak hours, multiple MU’s can be combined into a single train driven by a single train driver at the head (front) of the train. The single driver controls the engines and breaks of all the MU’s combined. There are a few cases in which MU’s, once coupled, even allow passengers to walk from one MU to the other.

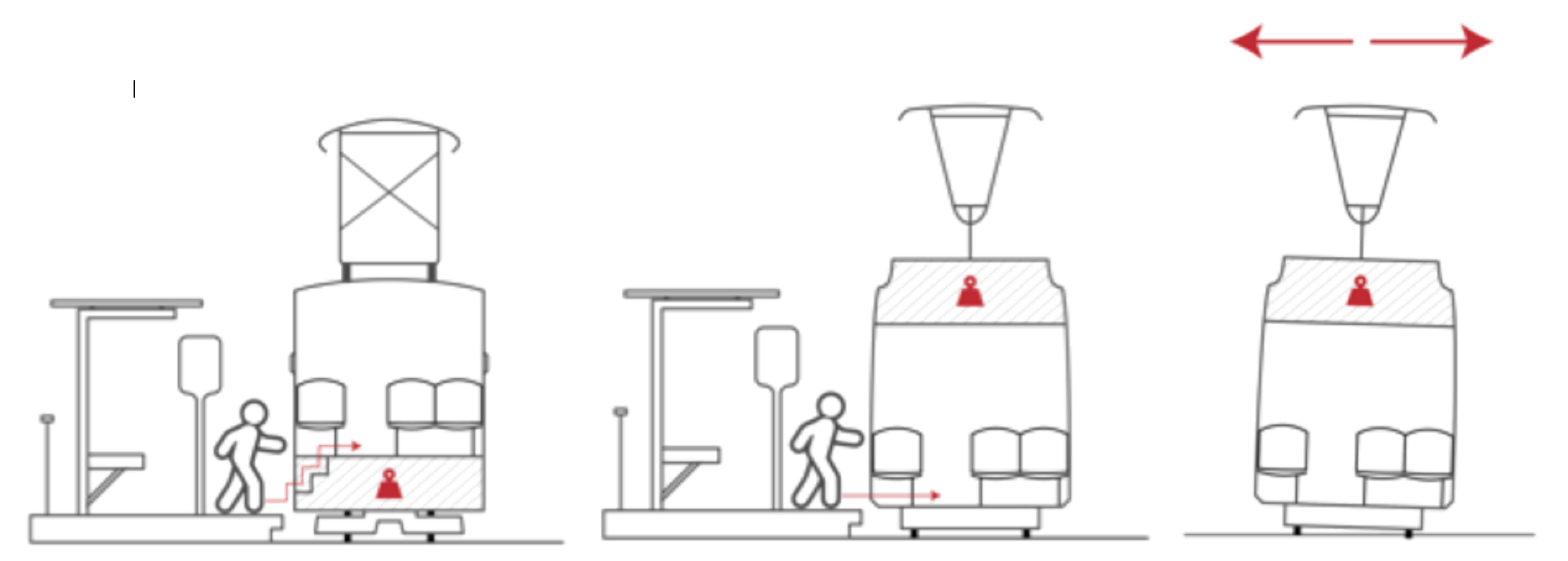

Visualised above are three ways of connections; from left to right by transit lock, without in both metro and train or by combining full train units.

1.3.2 Freight Trains

Why does a freight train often get priority over passenger transport if using the same network?

Many have experienced it at least once in their lives. While waiting for a railway crossing, a freight train passes by. This can take quite long, even minutes, since you can regularly count over a hundred cars passing by, and often at a limited speed. Not only can freight trains be multiple kilometers (or miles) long, they also carry all kinds of different goods, demanding different kinds of car type designs, which can create rather unexpected combinations.

In the series above, you will see from the first three wagons: an open wagon, closed wagon and flat car wagon and the rest: tank wagon, Schnabel cars and freight train with two locomotives (photo by Terry Cantrell, TU Delft and from PXhere).

Each type of car design has its own characteristics and features. Worldwide, many more types and spin-off designs of freight cars exists on the railway tracks, often in bright recognisable colours. Some of them even devoted to very special tasks, like the Schnabel cars, which are specially designed to carry really heavy or oversized loads, like electric transformers. The car consists of two beams, in which the load is suspended, supported on the track with a lot of wheels or bogies. This way, the load is part of the structure of the car. Using this many wheels allows for the heavy weight to be transported, and suspending the load allows the car to use normal track curves.

To move hundreds of freight cars, locomotives often are much heavier and stronger compared to passenger trains. The strongest locomotives currently available have over 19000 horsepower (comparable to approximately 19 Bugatti Veyrons!). Aside from normal locomotives for freight transport, special locomotives are often used for the shunting process. Since during shunting, speeds are not as high, but frequent acceleration and deceleration are required, locomotives have been specially designed to handle these kinds of jobs. In some cases, shunting locomotives can even work by remote control, so no extra train driver is needed, while wagons are being pushed rather than pulled.

When assembling a freight train, the most important things to consider are the gross weight of the freight vehicles, the terrain the train has to cover, the speed it has to travel by and the availability of overhead power supply. Both the weight of the train and the maximum incline determine the required traction for the total train. The required brake power is determined based on the weight and maximum decline. Based on these requirements, either one or multiple locomotives can be selected to be used in a train. In some cases, multiple locomotives are spaced out over the full length of the train for a better distribution of power. In the video below, a nice example is seen of a long freight train climbing a relatively steep incline in California, using 3 locomotives.

So freight trains can be really long and sometimes use the regular railway network, which makes them interfere with passenger transport. A situation can occur when you have an important meeting or time is running out to catch your connecting train at the next station and you suddenly stop. Minutes go by when nothing happens and then suddenly a freight train passes by. For the people sitting in the train, this incident may seem odd. Why not just let your train pass first?

The length of the freight train actually causes many more problems when it had to wait for you. It covers such a large part of the track that it often blocks multiple switches, railway crossings or even one or more bridges at the same time, which cannot open at that point. Also it might just be leaving a tunnel or entering one, both creating a situation where you really do not want to stop as a train driver. There are multiple examples, where freight trains get stuck in tunnels, since they do not have the power to pull all carriages out after standing still, because of an elevation on either side. Other reasons for this are the extremely long break-distance, the required power to get everything moving again and the time that it takes before the whole combination is back up to speed. For your train, it is much easier to stop for a moment, making sure the freight doesn’t interfere with the full timetabling schedule, creating delays for possibly dozens of passenger trains, which could just as well have been yours (or will be) the next time.

While this list of reasons might not help for why you missed the start of your meeting, it most likely helped many others to get in time to theirs.

1.3.3 Light Rail

What is the effect of a much lower entrance level on the design of modern trams?

To enable fast short connections within cities, light rail is often used. Light vehicles can accelerate fast and stop quite easy (rapid transit). Subway and tram are examples of this, as well as monorail, which also can be seen as a train type on itself. Light rail vehicles form an intermediate group, driving tram-like vehicles on higher speeds and on a dedicated infrastructure.

From top to bottom an older tram, a modern tram and a metro train (photo by Mario Roberto Duran Ortiz and Alstom). If comparing the older and more modern designed tram, the most profound change is the lower entrance level for passengers. Before this trams always had a little staircase (few steps) to get to the seating area, which was situated above all heavy equipment like the transformer, engine, computers and aircon. To improve comfort, this all has been moved to the roof in the new designs. This way people can enter the vehicle on street level.

From top to bottom an older tram, a modern tram and a metro train (photo by Mario Roberto Duran Ortiz and Alstom). If comparing the older and more modern designed tram, the most profound change is the lower entrance level for passengers. Before this trams always had a little staircase (few steps) to get to the seating area, which was situated above all heavy equipment like the transformer, engine, computers and aircon. To improve comfort, this all has been moved to the roof in the new designs. This way people can enter the vehicle on street level.

Situating this mass higher, creates an unbalanced vehicle. Especially within corners (and therewith switches), left to right movement increases a lot which damages the track. Knowing that trams make rather sharp turns emphasises this even more. This almost ‘nervous behaviour’ makes the flange scrape the rail, causing a large amount of wear with each wheel passing.

More details on the contact and interaction between rail and wheel will be discussed later this week. In the section on wheel/rail interface, we will also look at the problems which occur when putting light rail vehicles on heavy rail infrastructure.

Monorail

Monorail vehicles can also be categorised under light rail, although Monorail almost is a transport type on its own. Monorails use only one instead of two rails, and can roll or (as most people will recognize it) use magnets and levitate over it. In week 6, we will take a close look at how this and other special systems work and where they can be found in the world.

In practice, there are no clear boundaries or numbers that distinguish heavy rail from light rail, when looking at axle loads. The categories are even differently interpreted in different locations around the world. What is most important is that most suitable vehicle types and design for specific purposes, which mainly depends on number of stops. In addition to the weight, important factors and properties are acceleration, angle of corners, but for example also the number of doors. A higher frequency of stops is often related to the limited time on the platform, which then directly influences the number of doors to facilitate a fast process of exiting and entering the train.

1.3.4 High-speed trains

Why does China invest in high-speed trains rather than in domestic airline connections?

High speed trains are designed for operational speeds of over 200 km/h. Some are able to reach speeds up to around 400 km/h during commercial operation, and a world record has been set at over 550 km/h during test-phase. In order to achieve these kinds of speeds, both a special infrastructure and special rolling stock are needed. If an electrified high-speed train actually reaches a speed that high, the catenary system (more details in the next section) will need significant repairs after each train that passes. The forces on the pantograph will become higher than it can handle, and it might even break down during the first test. Catenary systems (as they are designed in 2017) are usually able to handle speeds op to 350-400 km/h, when looking at a life-expectancy longer than a year.

Above a European ICE high speed train (photo by Sebastian Kasten), a Chinese high speed (Zili Li) and the Shinkansen in Japan (Tansaisuketti).

Above a European ICE high speed train (photo by Sebastian Kasten), a Chinese high speed (Zili Li) and the Shinkansen in Japan (Tansaisuketti).

Looking at high speed infrastructure compared to regular systems, differences can be found, for example, in the allowable radiuses in track curves. Due to higher speeds, larger radiuses are needed in order to keep the ride comfortable. This results in high speed railways being less able to follow terrain, thus having more bridges and tunnels, increasing costs and making it more difficult to implement within dense areas.

There are also differences in the tolerances for the infrastructure itself, both for the rail and the catenary. Even on a straight track, the rail is never 100% straight. There will always be some margin of error in this track alignment, introduced in building the track, of which the tolerated error is specified. For high speed tracks though, the tolerated error in the track alignment is much smaller. This is because, using the same margins as for normal tracks would increase the risk of derailment in high speed trains. Constructing a track with these smaller margins results in higher construction costs for the track itself, often requiring better foundations, etc.

In railway vehicles, there are also some clear differences between normal and high speed railways. The clearest difference can be found in the aerodynamics. At higher speeds, air resistance goes up quadratically. Doubling the speed would make the power consumption to overcome the air resistance go up by a factor of 8! Reducing air resistance thus becomes extremely important for achieving high speeds. This can be seen in the typical long-nose that most high speed trains have, but also in the integration of the pantograph on the train. Other details you will often find are, for example, putting a cover on the coupling mechanism at the front of the train, minimizing the gap between coaches, and installing side skirts underneath the train. Aside from the aerodynamics, differences can be found in many other aspects of the vehicle as well. You can think about different bogies, power distribution systems, closed toilet circuits (like in airplanes), windows that cannot be opened, and many more.

Over long distances, it might be logical to expect air traffic as main way of transportation, but as mentioned at the start of this section, China chose instead to invest in fast train connections between main cities. The large amount of people, with an increasing demand every year, is the main reason for this decision. Trains can easily carry a thousand passengers at once, whereas planes are often limited to a few hundred and even the largest passenger aircraft will not get to that number. Trains also can run at a much higher frequency and railway stations can be placed much closer to the desired location, often even within the heart of a city or business district. An additional advantage is the limited time to board, since for domestic train travel customs and security delays are limited to a minimum. Apart from all this, trains are reliable, safe and fast, especially in modern designs of both infrastructure and rolling stock and trains are better for the environment as they run on clean energy.

1.3.5 Maintenance Vehicles

Why are road vehicles used to maintain the railway track (using small attached steel wheels) rather than an actual train?

Maintenance and inspection vehicles are an unusual appearance on the track. These special vehicles are designed to repair and/or replace (parts of) the track. They often have a dedicated purpose, such as tamping the ballast, grinding the rail surface or doing a single dedicated type of measurement. Some can even replace the sleepers and ballast bed underneath them, while driving slowly over the track, operating like a complete factory on wheels, like seen in this video (source: Strukton Rail).

Because it can be very expensive to close down a part of the track, while it is being maintained, it is common that these trains run at night to minimise the impact on the regular schedule.

In some cases when maintenance or measurements have to be arranged quickly, getting a train to the right location might not always be the best solution. Road vehicles often have easier access by not being restricted by train paths. These ‘hybrid vehicles’ are equipped with an extra set of wheels, which they can deploy in order to be able to run on the rail. Since the capacity is much more limited, compared to full maintenance trains, this solution is used mostly for high priority repairs on specific parts of the track, but with many small disturbances happening each day, hybrid vehicles can be seen rather often. Railway crossings are used to enter or leave the tracks.

From left to right: two maintenance vehicles and a hybrid vehicle using small steel train wheels

From left to right: two maintenance vehicles and a hybrid vehicle using small steel train wheels

Railway Engineering: An Integral Approach by TU Delft OpenCourseWare is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Based on a work at https://ocw.tudelft.nl/courses/railway-engineering-integral-approach/.