2.3.1 Types of joints

Course subject(s)

Module 2. The Building Blocks of the Exoskeleton

If we have an exoskeleton with a frame we have a static structure, but if we want to be able to walk we need actuators. An actuator converts energy into movement or force. In an exoskeleton, these actuators are called the joints. The main goal of the joints is to move the bones of the exoskeleton relatively to each other.

First of all, there are a lot of different types of joints that can be categorized in many different ways. As you can imagine, tiny drones or small robots need different actuators than large cranes in large cargo ports or in the automotive industry. Exoskeleton actuators should be able to deliver enough rotational force and speed but should also be small and lightweight. And even within these requirements, there are still quite some options. Not all possible actuators are explained in this reading, but the most common ones will be.

Passive and active joints

In exoskeletons, you can use passive and active joints. Active joints are actuated where passive joints are not. Passive joints are connection points between bones. With an axis, the bones can turn around, with optional non-actuated parts such as springs attached to them. You can’t control the precise position of the joint within the outer limits. Active joints are more common in exoskeletons since you often want control over the position of limbs and therefore the joints. If a passive joint is used, it is often the ankle joint. You don’t need to power this joint to be able to walk, although you lose some control over the exoskeleton position if you don’t. Joints can move in different ways. In linear joints, two parts glide past one another without changing the angle between them and without rotation. The mobile part retracts and extends from its housing.

Linear and rotary joints

Joints can move in different ways. In linear joints, two parts glide past one another without changing the angle between them and without rotation. The mobile part retracts and extends from its housing.If a linear joint is placed around a passive rotating joint, it turns the passive joint into an active joint. By shortening and lengthening the linear joint, the bones start rotating around their connection point.

Figure: Motion of a linear joint

If a linear joint is placed around a passive rotating joint, it turns the passive joint into an active joint. By shortening and lengthening the linear joint, the bones start rotating around their connection point.

Figure: Motion of an actuated linear joint and passive rotational joint

As the name already suggests, rotary joints make the bones on both sides rotate respectively to each other.

Figure: Motion of a rotary joint

Although these rotary joints might look more similar to the joints in our body, our body actually uses the same mechanism as the combination of a linear joint and a passive rotary joint. The joints in our body are simply connections between bones that allow movement in certain directions. By contracting and releasing the muscles that are connected to the bones on either side you are able to move your limbs! In exoskeletons, rotary joints are used more often. They can deliver enough rotational force and speed, but with a larger range of motion and a more compact design compared to linear joints.

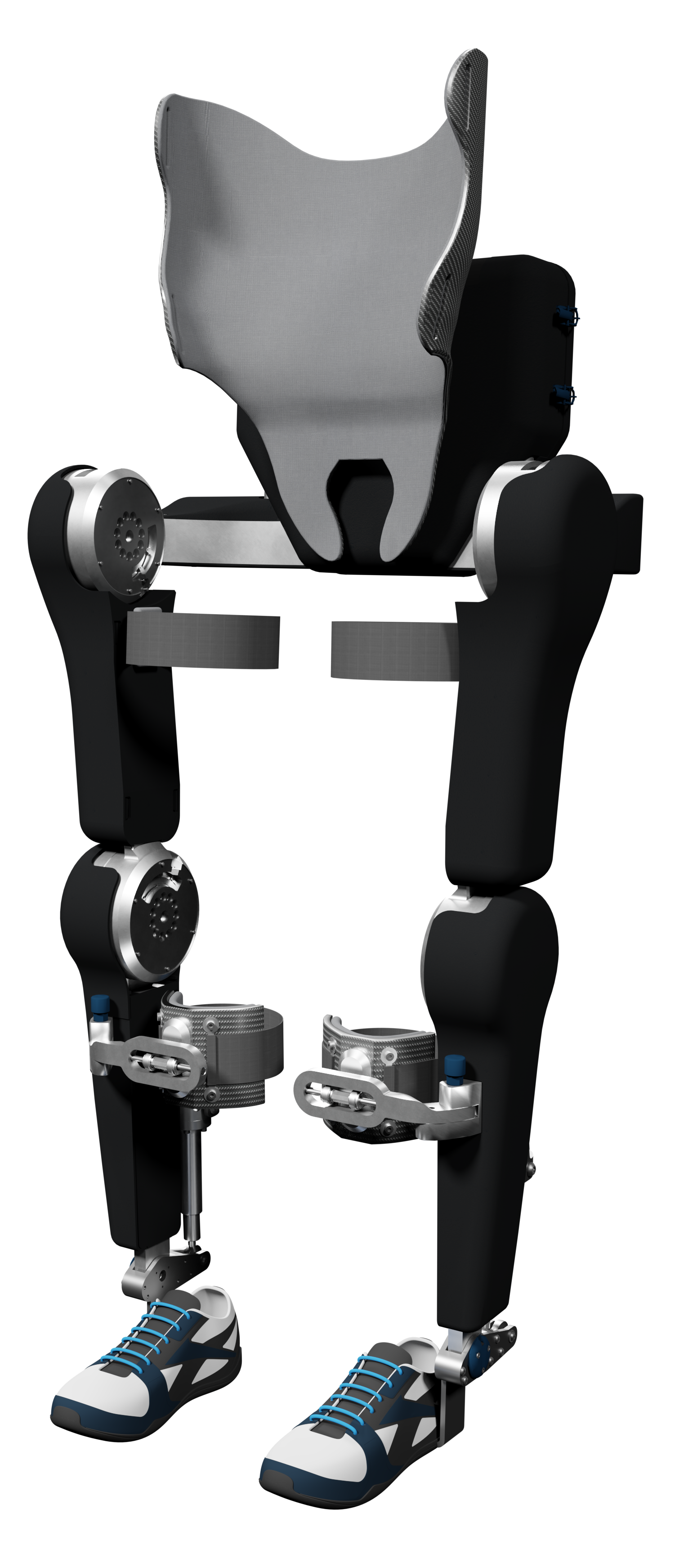

In the MARCH IV exoskeleton, both rotational and linear joints are used. As you can see in the picture below, the knees and hips are equipped with rotary joints. The hips also have linear joints for a sideways motion, and so do the ankles.

Figure: Render of the March IV exoskeleton

Electric, hydraulic and pneumatic actuators

Actuators can be powered by electricity, but also by pressurized air or fluids. All these types have their advantages and disadvantages. At this moment, most exoskeletons use electric actuators.

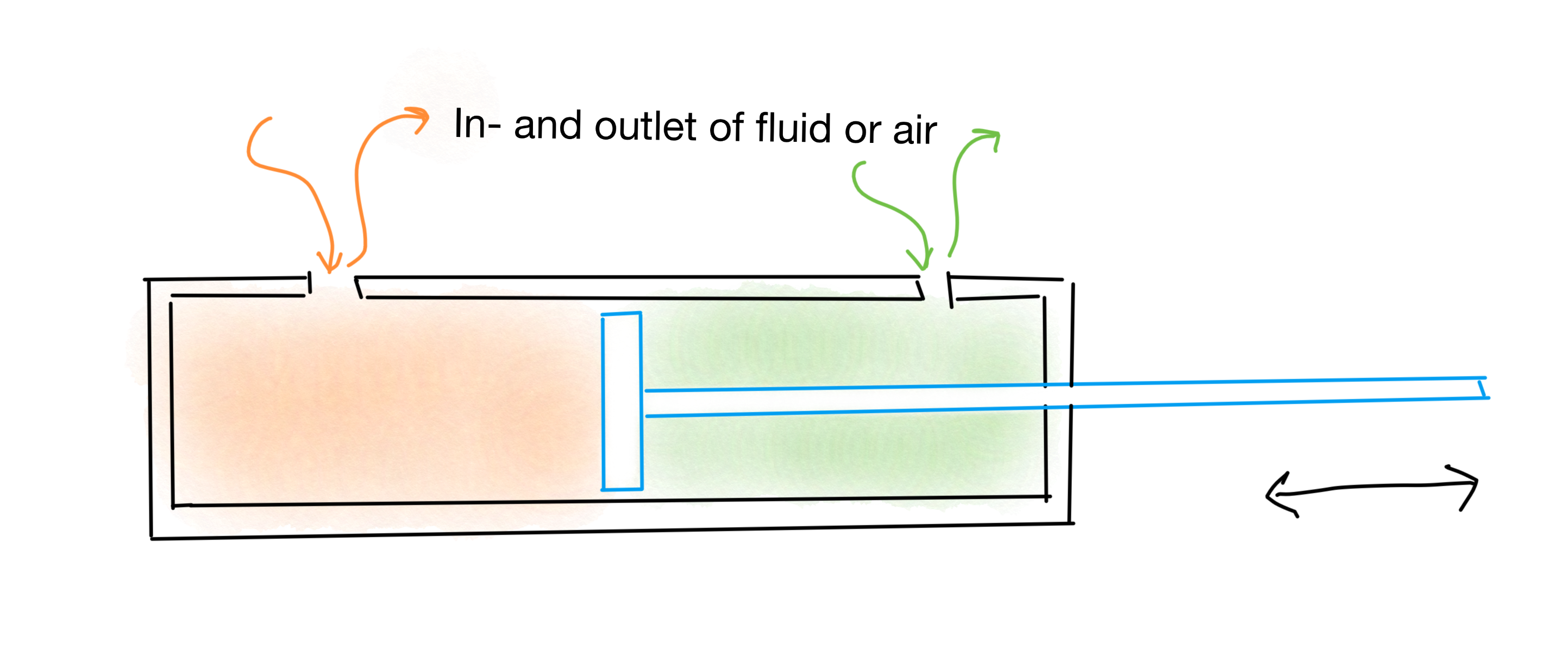

Pneumatic actuators are powered by pressurized air. By moving compressed air to different compartments within a joint, the position of the joint can be determined. Pneumatic actuators are quite safe since they do not contain any hazardous materials, although high pressure itself can always lead to unsafe situations. On the other hand, they deliver little force to power the exoskeleton (it is possible though) and they have quite a low efficiency due to air leakage. If you want to accurately control the actuator, you need regulators and valves, which complicate the design and increase the weight, dimensions, and costs.

Figure: Pneumatic or hydraulic linear actuator

Hydraulic systems operate quite similar to pneumatic systems, but with the use of fluids instead of air. They can generate very high forces. Although there is a loss of efficiency over time due to leakage of fluid. Leakage of fluids can also cause damage to the surrounding systems. It requires reservoirs, pumps, valves, and more to be able to have precise control over the actuator and therefore greatly increase the complexity and weight of the exoskeleton.

Electric actuators offer very precise control and are quick and easy to use. They can generate quite some power and are more quiet compared to both hydraulic and pneumatic systems. They are relatively compact and lightweight, which makes them suitable for exoskeleton use.

Electric motors and transmission

When using electrical actuators, there is a difference between the motor and the transmission. The motor actually uses electricity and converts it into movement, or kinetic energy. Transmission converts it into the movements that you actually need. On the next page, there will be a video with some explanation on different types of transmission and how you can do some calculations on transmission. In exoskeletons, it is very common to use a drone motor or another small motor that has a high rotational frequency, combined with a transmission that slows down the speed and increases the rotational force.

You can also combine hydraulic, pneumatic, and electrical systems. You can, for example, use an electric motor and combine it with a hydraulic transmission system. The benefits of combinations like this are that you get to combine favorable properties of both systems and reduce the disadvantages.

Overall, there are many different types of actuators for a great range of applications. By being precise in establishing your list of requirements you should be able to pick the right joint for your exoskeleton.

Project MARCH: behind the technology of robotic exoskeletons by TU Delft OpenCourseWare is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Based on a work at https://online-learning.tudelft.nl/courses/project-march-behind-the-technology-of-robotic-exoskeletons/